Sensor-based sorting systems enable the removal of individual objects or particles from a material sream. The technology is widely used in various sectors such as agriculture, the food industry, mining and recycling. Examples of sorting tasks include the removal of fungus-infested seeds, the enrichment of ores in mining or the sorting of plastic waste. Sorting decisions are made based on information recorded by one or multiple sensors about the material. A particular strength of the technology is its flexibility regarding sorting decisions. This flexibility is achieved through the use of different sensors, possibly their fusion and intelligent data analysis.

The functional principle

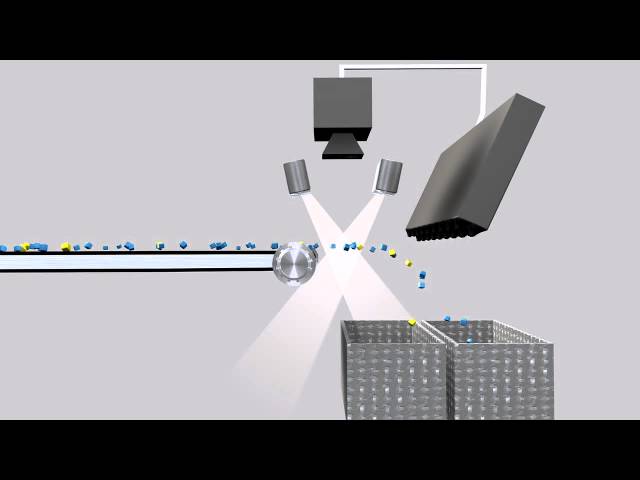

Sensor-based sorting consists of various process phases: Material feeding and transportation, sensory examination, data processing and material separation.

The material is fed into the system via a conveyor mechanism, e.g. a vibratory conveyor. The material is then transported further, for example via a conveyor belt, a chute or even in free fall. During this transport phase, the sensor data is recorded by one or multiple sensors. The sensor data is processed with the aim of detecting and classifying individual particles in the material stream. The classification result serves as the basis for the sorting decision, which is carried out by means of actuators by ejection. An array of pneumatic fast-switching valves is most commonly used for this purpose. Theoretically, any number of classes can be differentiated, and separation into several fractions is also possible. In industrial applications, however, the task is usually implemented as a binary sorting task, i.e. sorting into "product" and "residue".

Our drive

We are experts in sensor-based sorting systems, researching and implementing new solutions for previously unsolved sorting tasks.

Our developments are aimed at overcoming existing technological limits and thus developing successful solutions for unsolved sorting problems. Our focus is on sensor selection, data acquisition and real-time sensor data processing.

Our laboratory equipment enables us to examine samples with a variety of modern sensors and thus identify the optimum solution for a sorting problem - both in terms of detection quality and economic aspects. In our technical center, we also have a large number of modular sorting systems that can be upgraded for new tasks and enable sorting tests to determine the selectivity or other parameters such as energy and compressed air consumption.

We cooperate with numerous other Fraunhofer Institutes and other research partners from a wide range of disciplines. This large network enables us to tackle highly interdisciplinary issues related to sensor-based sorting.

We develop the sorting solutions of tomorrow!

Our services

- We characterize your materials optically, develop classification models, work out lean sorting solutions for your application and test the selectivity with the help of our laboratory and pilot plant equipment.

- We have mobile test systems - with these we can investigate sorting issues directly at your site, on a construction site or at a production facility.

- We conduct research into AI-based solutions for previously unsolved sorting problems and develop corresponding software solutions.

- We can advise you on all aspects of sorting technology and, on request, support you in setting up the appropriate processing and purification steps.

- We are involved in numerous publicly funded research projects to improve sorting systems for unresolved issues in order to solve current social challenges, such as achieving a circular economy

- We advise you on all aspects of sorting technology and support you in the implementation of sorting solutions.

- We also hold seminars for your employees to introduce them to the topic.

Fraunhofer Institute of Optronics, System Technologies and Image Exploitation IOSB

Fraunhofer Institute of Optronics, System Technologies and Image Exploitation IOSB